SonicWave Clean reduces particle and oil fouling and allows the refrigerant to flow without disturbing the desiccant or allowing foreign materials to circulate in the refrigerant past the filter/drier. The SonicWave Clean reduces energy consumption by an average of 14.5% in HVAC systems by reducing the back pressure in the liquid line filter / drier.

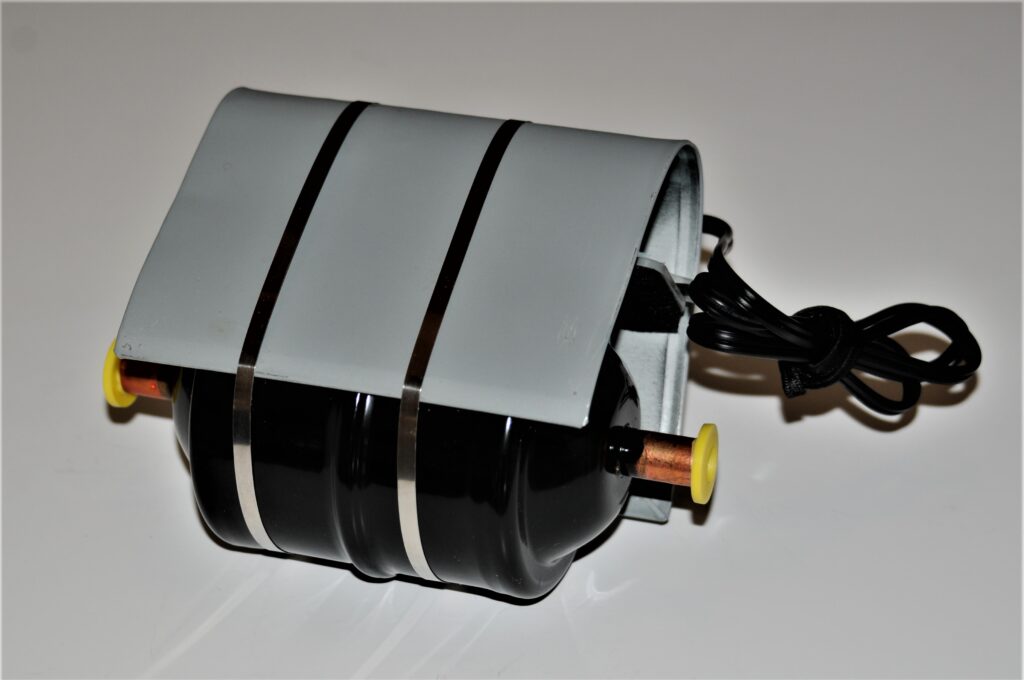

What Is It?

The SonicWave Clean is an electronic device that conducts sonic and ultrasonic waves into the filter/drier used on HVAC systems. This reduces the RFD refrigerant flow resistance and the energy required to move the refrigerant through the refrigeration circuit.

How Does It Work?

The SonicWave Clean generates pulsed sonic & ultrasonic waves which interact to loosen and remove sludge from the filter screens. This reduces restrictions in the cells of the screens reducing the energy needed to keep the refrigerant flowing.

- SonicWave Clean- imparts low pressure sonic & ultra-sonic waves into the liquid line filter / drier, to reduce resistance to the flow of the refrigerant.

- SonicWave is designed for use on DX (Direct Expansion) units with in-line liquid line filter / driers.

- SonicWave is recommended for any system where the “Delta T” on the liquid line filter / drier is over 2.5° Fahrenheit / 1° Celsius. An elevated Delta T indicates restrictions in the liquid line filter / drier.

- SonicWave will reduce the energy used by 11%-21% depending on the amount of oil fouling in the system.

- SonicWave is economical and cost effective, in comparison to changing filter / driers.

- Typical filter / drier replacement for a 15 ton, dual circuit HVAC is over $900.00 and takes the system out of service for more than 6 hours but does not result in a reduction of energy usage.

- SonicWave takes 20-30 minutes to install when installed by an HVAC technician and costs less than $550.00, with the added benefit of reducing the energy used from an average of 12-19%. The SonicWave will produce a ROI in excess of 500% over the life of the system.