What Is It?

Chemsonic Catalyst® is a synthetic catalyst technology that helps HVAC / Refrigeration systems operate more efficiently by reducing oil fouling. Systems that operate closer to their engineering design operate less and use less energy to achieve and maintain the desired temperature set point. Chemsonic Catalyst® has been proven to reduce HVAC / Refrigeration KWH energy usage by up to 22–28% in systems treated. The technology contains 3 separate components that collectively produce the results.

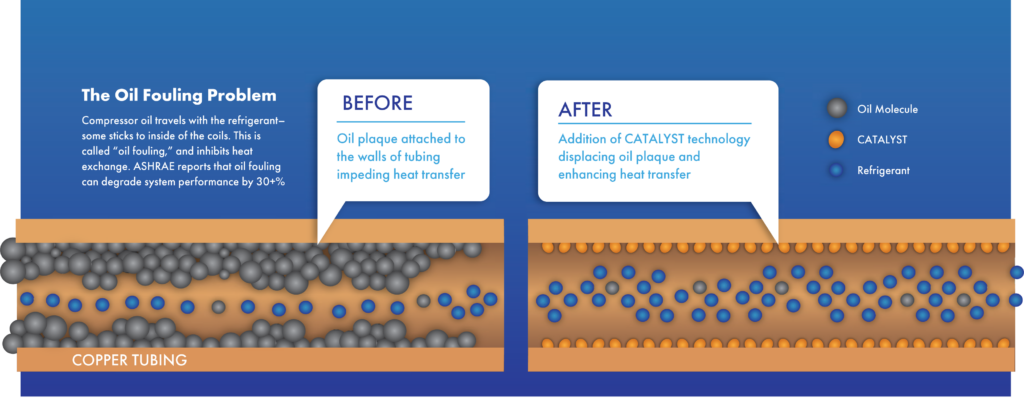

What Is Oil Fouling?

Compressor oil moves throughout the system with the refrigerant. Oil molecules adhere to the coils and tubing which reduces heat transfer. ASHRAE states that oil fouling can reduce system efficiency by 30+%. BEFORE utilization of Chemsonic Catalyst® oil fouling molecules adhere to coils and tubing which reduces heat transfer and efficiency. AFTER using Chemsonic Catalyst® oil fouling molecules on the tubing and coils are reduced, restoring the system’s heat transfer ability and efficiency.

How Does It Work?

Chemsonic Catalyst® achieves the energy savings by allowing the system to operate less while at the same time delivering cooler air to achieve the temperature set point faster. As a general statement, Chemsonic Catalyst® does make the system use less energy when it is operating because it allows the system to run less.

- The first catalyst defeats the surface tension (van der Waal force) that causes the compressor oil molecules to adhere, not only to each other, but to the system’s walls and tubing. The removal of oil-fouling restores 20-34% loss in heat transfer capability. Additionally, the capillary tubes and expansion valves are cleaned and protected from future fouling.

- The second catalyst causes the refrigerant to evaporate or “boil” at a slightly lower temperature – typically from .05 F to 1.5° F. The cumulative effect of these 2 catalysts working together results in up to 73% improvement in heat transfer capability.

- The third ingredient is a lubricity agent that improves the lubricity of the compressor oil by as much as 54%. These findings are substantiated by a SAE (Society of Automotive Engineers) 4-ball lubricity test performed by Intertek Laboratory. This allows the compressor to run smoother, quieter and cooler. The audible sound is greatly reduced as the lubricity agent is circulated in the compressor. The cumulative result of the catalyst working together along with the lubricity agent in the system produces the reduction in the system’s energy requirement. No single agent or catalyst could produce the same results in system efficiency.

What Does The Catalyst ® Do?

- Reduces your electric energy cost by 20% or more.

- Delivers colder vent air faster, allowing the compressor to operate less.

- Reduces the relative humidity by an average of 15%.

- Reduces equipment repair cost.

- Reduces compressor noise and vibration.

- Extends equipment life because the equipment runs cooler.

- Lasts for the life of the system (in DX units). In chillers, a small booster charge is required after the third oil change, (7-8 years).

- Provides the most cost effective way to further enhance system SEER (Seasonal Energy Efficient Ratio).

- Reduces carbon emissions and greenhouse gases.